A Guide To Choosing The Right Floor System

To create the home you’ve envisioned for years, there is a seemingly endless number of details to consider. Once you have reworked your floor plan and adjusted the home’s orientation and window placement to take advantage of your property’s views, the next important detail to focus on is your floor framing system? Unlike floor finishes, the floor framing system will become part of your structure for the life of your home. At Pacific Truss, in addition to multiple wall framing systems, including our Pacific SmartWall® System, we offer three major types of floor framing systems. A look at the advantages of each system will allow you to select a floor tailored to your design that will offer exceptional performance over the life of your building project.

DIMENSIONAL LUMBER

The original workhorse of wood frame construction! There are plenty of good reasons to use this trusted standby in your home. Typically, 2×10 (9 ¼”) and 2×12 (11 ¼”), nominal joist depth lumber species are grouped by similar performance characteristics and are graded by structural quality. This allows for designers to ensure properly sized joists and beams are used for specific loads and spans. The specific category and grades of these will vary by region. In BC, and in Pacific Homes packages, the base standard is Spruce/Pine/Fir grade #2 (SPF #2) or better, but for example, when required for a specific beam or span, a Douglas Fir/Larch grade Select Structural (DFIR-L SS) may be used.

Dimensional lumber is often the most economical choice, but that is not its only advantage. It is also durable in shipping and installation. Kiln drying and protection from the elements in transit and during construction helps reduce swelling across the wide grain and keep lumber dimensionally stable. Prefabrication is great for this. However, if the lumber is exposed to moisture, but then permitted to thoroughly dry out, the moisture will not have a significant detrimental effect on the structural integrity of the lumber. Therefore, pressure treated lumber is the go-to material for decks exposed to the weather.

I-JOISTS

The same year Pacific Truss started manufacturing wood trusses (1969), a small company from Idaho, called Truss Joist Inc. created the first wood I-joist. Which is why I-joists are sometimes referred to as TJIs, the pioneering brand name. Now, over 50 years later, I-Joists are a staple of the industry and every major wood products supplier offers their own line of I-joists.

Similar in design to the steel I-beams used in heavy construction for decades prior, wood I-joists gain their mechanical advantage from their I shape profile. Two horizontal lumber flanges are joined by a vertical Oriented Strand Board (OSB) web. Standard I-joists depths vary from dimensional lumber at 9 ½”, 11 7/8″, and 14″. For long spans, depths up to 24” are available at 2″ increments.

To achieve longer clear spans and carry heavier loads without increasing the depth of the I-joist, the size and structural grade of the flange is increased. For example, where a standard I-joist would use a 2×3 SPF #2 or better flange, a higher end series in the same depth would use a 2×4 Machine Stress Rated (MSR) flange.

As Engineered Wood Products, I-joists are sized by an engineering technologist to meet specific requirements with regards to span and loading in a custom home. An analysis of the resulting design is reviewed and sealed by a professional engineer and supplied to the installer and building inspectors.

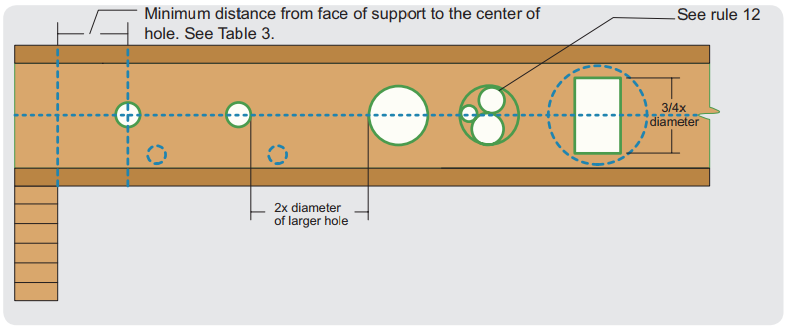

As there is some variation in dimensional lumber floors, installation instructions are provided with the floor material. This includes details on drilling holes in the OSB webs. Both size and placement of holes are very flexible in I-joists.

The I-joist manufacturing process allows for long continuous lengths to be produced which is only really restricted by shipping and site considerations. This, along with the relatively light weight design of the I-joists, allow for quick installation, which reduces joints and blocking.

As a manufactured product, I-joists are dimensionally stable, consistently straight and any shrinkage is negligible. Defects such as crowning, twisting, cupping, and warping, seen in dimensional lumber, are not an issue. High quality finished floors are the result.

The smaller lumber and wood fibers comprising the I-joists allow smaller logs and raw logs to be used. This, coupled with sustainable tree farming and logging practices employed by the major manufacturers, makes the I-joist an environmentally friendly product. Along with other components and considerations, incorporating I-joists into your house design may qualify your home for certifications such as the LEED Green Building Certification.

FLOOR TRUSSES

Similar to roof trusses, floor trusses utilize dimensional lumber, most commonly 2×4, for the top and bottom chords, and webs of the truss. All connections are made by steel plates pressed into the wood. Differing from roof trusses, floor trusses typically have the lumber oriented as 4×2 or ‘on the flat’. This allows more room for the webs at a shallower depth than what would be required with the lumber in the opposite orientation. This is why floor trusses are often called 4×2 trusses.

The length that a 4×2 truss can span is only really restricted by the depth of the truss. While depths as shallow as 10 inches are possible, 4×2 trusses really become the competitive choice around 14-16 inches depth. So, for some designs or areas with height restrictions, they may not be the best option. Within a particular depth, the species and grade of the lumber, the number of webs, and the size of the steel plates at connections can increase the span and load carrying capacity of the truss.

Floor trusses are similar to I-joists in that they are specifically designed by an engineering technologist, then reviewed and sealed by a professional engineer, with documentation provided to the site. They differ however in that they are produced in a truss plant. We at Pacific Truss produce them at our Cobble Hill facility. This provides the opportunity for flexibility in the design, such as top chord bearing trusses and sloped top chords for deck areas.

As the lumber can be spliced with steel connections, continuous spans across a building are typical. The trusses are precisely sized so there is no cutting is required on site, increasing the speed of installation.

The open webs allow for electrical, plumbing, and mechanical to pass through, with no drilling required. While webs can’t be cut, drilled, or modified, larger openings can be accommodated at the design stage, making floor trusses the most flexible system in this regard.

As they incorporate smaller dimensional lumber, trusses see similar dimensional stability and reduced defects as I-joists. Also, similar environmental benefits are realized.

While it may seem the consideration of options and decisions are endless at the design stage of your home, determining the appropriate floor framing system is a crucial component of perfecting your next building project.